UX on the factory floor.

At a Glance

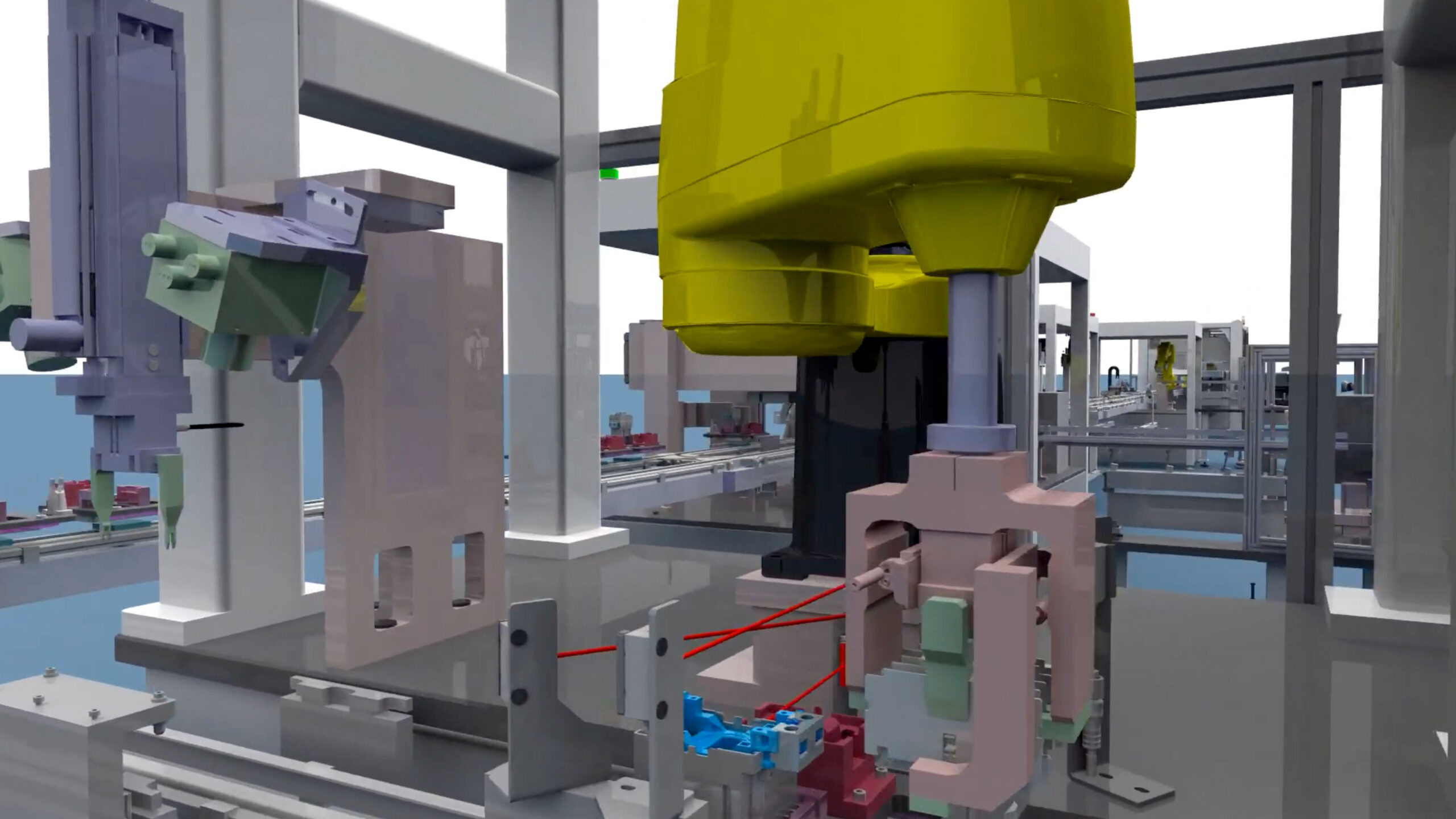

Owens Corning trusted Aquent Studios to help improve its manufacturing and industrial automation software for its 20 fiberglass plants.

Capabilities Engaged

- Prototyping

- UX Research & Design

Project Overview

Challenge

Owens Corning (OC) invented a process to make centrifugally spun fiberglass wool, which became the standard process for producing fiberglass insulation. In addition, they were the first to distinguish their product by dying insulation pink and the first company ever to trademark coloring. Over the years, OC has become the world's largest manufacturer of fiberglass composites and operates over 60 plants worldwide. However, over the past 15 years, the software used to run its 20+ fiberglass plants became more of a liability than an asset and generated more than 30% of all IT technical support calls at the company.

Approach

We helped Owens Corning leverage modern agile and UX practices to design the new plant floor system, a first for its IT organization.

What We Did

User Research

Walking in the user's boots

Mapped out a plan to conduct on-the-ground user research at multiple plants. Executed iterative and rapid prototyping to develop proof-of-concept solutions.

Mapping out the journey and users

Conducted multiple plant visits to research, observe, and understand the manufacturing process and the plant floor operators. Through contextual inquiry, journey mapping, and persona development, the team could see all the plant floor needs and pain points like never before.

UX Strategy

Uncovering new opportunities

Facilitated plant stakeholder workshops to share insights and to identify desired outcomes, current challenges, and new opportunities that helped inform longer-term strategy and roadmaps.

UX Design

Designing for the plant floor

Leveraged UX design, rapid prototyping, user testing, and agile methods to quickly design and develop new manufacturing execution system screens.

Accelerating time to insights

Worked with Plant Process Engineers to uncover and address analytics gaps, designing and developing state-of-the-art analytics dashboards and tools to enable equipment and plant efficiency analysis in minutes, not weeks.